The cold storage industry is characterized by the tasks that must be performed with unprecedented precision, incredible efficiency, and unwavering reliability. To enable the companies to meet these requirements, an innovative solution that can help them optimize their operations, reduce expenses, and ensure adequate quality with nominal waste is required. This article aims to show how technology is revolutionizing the cold storage industry by proposing the use of custom software.

Tailoring Software to Your Cold Storage Needs

The cold storage industry faces singular struggles that require innovative remedies. Ready-made programs can provide base features but personalized development crafts tailored tools precisely matching goals.

Benefits of Custom Software for Cold Storage

Collaborating closely, programmers personalize a system solving storage’s struggles, from stock supervision and thermometry tracking to rule respecting and energy economizing. A solution surgically styled for the situation means seamless operations, limiting liabilities and maximizing savings. Safely keeping perishables intact increases incomes.

Key Features of Custom Cold Storage Software

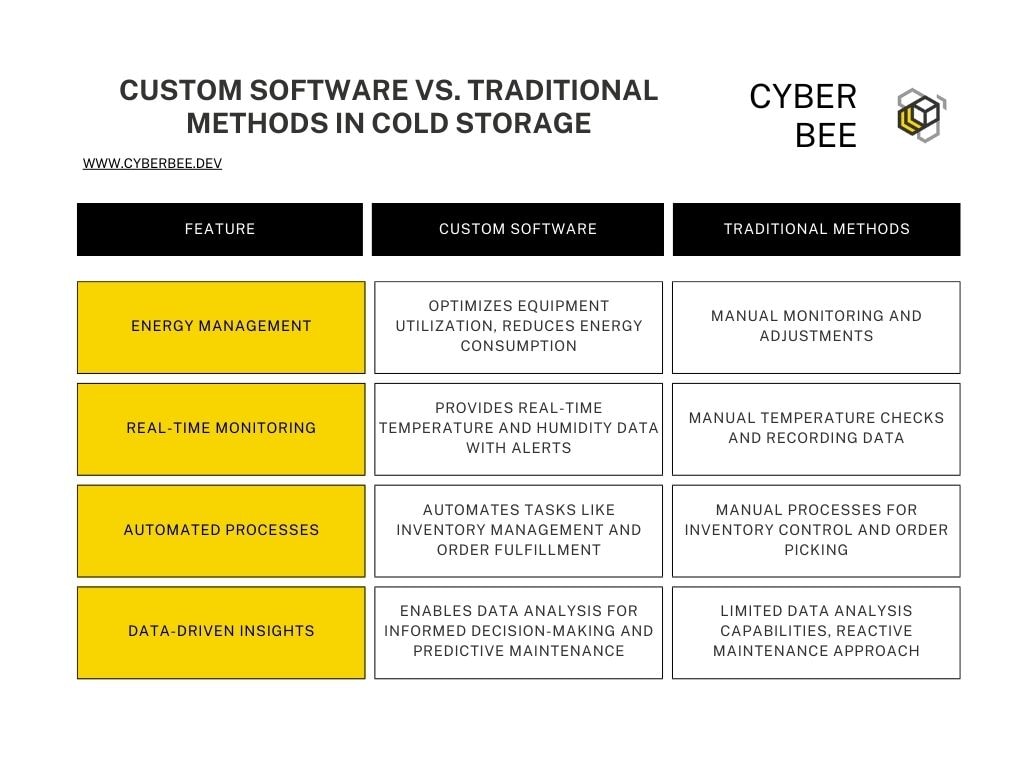

Custom software solutions optimize facilities by augmenting workforce productivity and resource efficiency. Core capabilities include:

- Energy Management: Optimize equipment usage, curtail energy expenditure, and extend asset life spans through smart software management.

- Real-time Monitoring: Deploy sophisticated sensors and alerts to preserve precise temperature and humidity regulation, safeguarding commodity integrity.

- Automated Processes: Streamline logistics by automating tasks such as inventory administration and order fulfillment, freeing team members for strategic initiatives.

- Data-Driven Insights: Leverage software to compile and examine data, enabling informed decision-making and predictive servicing.

For example, an artfully designed software system can maximize the utilization of your freezers and other storage apparatus, preventing energy waste and extending the lifespans of your assets. By integrating real-time temperature surveillance and alert mechanisms, you can proactively address possible issues and shield the integrity of your stored products. In addition, personalized software solutions can systematize your workflows by automating routine tasks, for instance inventory administration and order fulfillment. This releases your dedicated team to center on higher-value duties, improving overall productivity.

Ultimately, a tailored software solution empowers you to take control of your cold storage operations, confirming adherence to industry standards and regulations while delivering exceptional service to your clientele.

Warehouse Management System (WMS) for Cold Storage

Warehouse Management System (WMS) is a software application intended to streamline and control the activities within your facility. Cold storage, where a WMS is crucial for managing inventory and movement of product while maintaining the required temperature.

Core Features of a Cold Storage WMS

A cold storage-specialized WMS should be able to offer features like lot tracking as well as expiration date alert and temperature-monitoring functionalities. This has resulted in a mix of product quality and regulatory adherence. In addition, by managing the Warehouse slotting through WMS efficient putaway and picking processes allow for optimal warehouse space utilization and labor productivity.

Advantages of WMS Integration

WMS solution will enhance operational efficiency, check costs and improve overall performance of cold storage facilities. Businesses are enabled to stock smartly, reduce the chances of being out of stock and prevent products from spoiling — align with a responsible shortage or wastage.

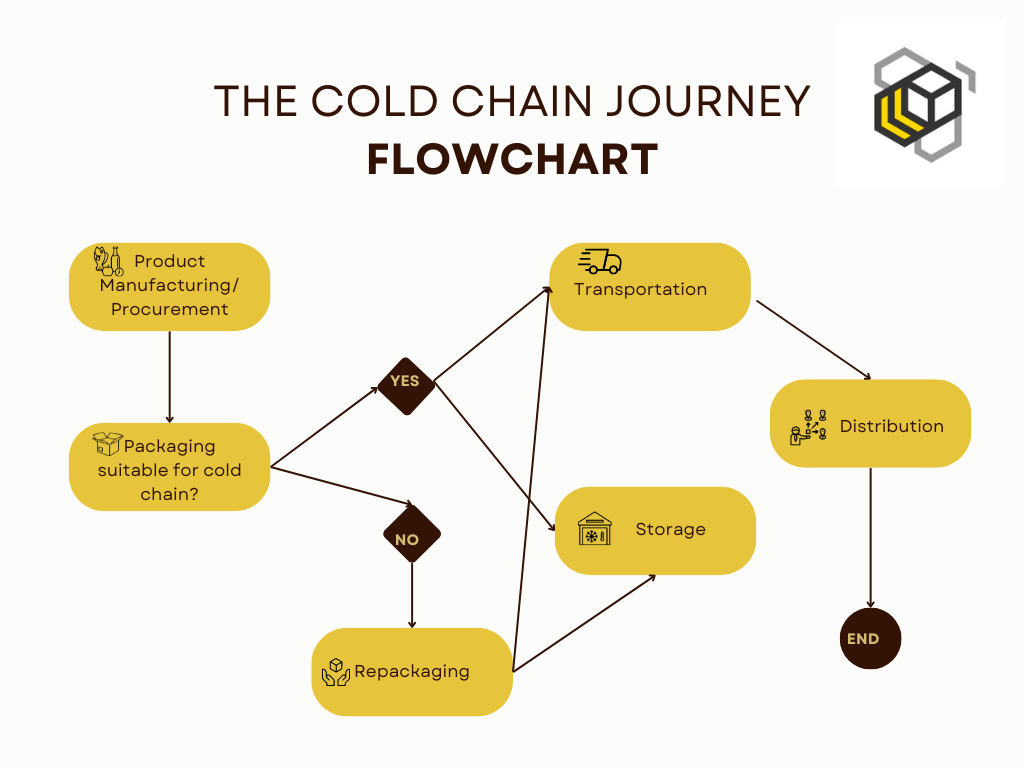

Software’s Role in a Cold Chain Optimization

Cold chains are complex logistics networks that maintain the integrity of a product from source to point and sale. They’re fragile and finding a solution that does not reduce quality while maintaining productivity standards is crucial.

Enterprises can outsource a full range of logistics tasks from procurement to distribution via strategic solutions that will enhance operations at every stage. For example, they can arrange transport and warehouse command systems that keep tabs about the condition of items an in-process shipments receive better coordination along with optimize routes for deliveries.

Being able to monitor environmental controls and movement in real-time allows for issues to be more proactively dealt with. By integrating applications, visibility remains available at all times by monitoring location data as well temperature and humidity sensors across systems (ERP) and TMS for full operational control.

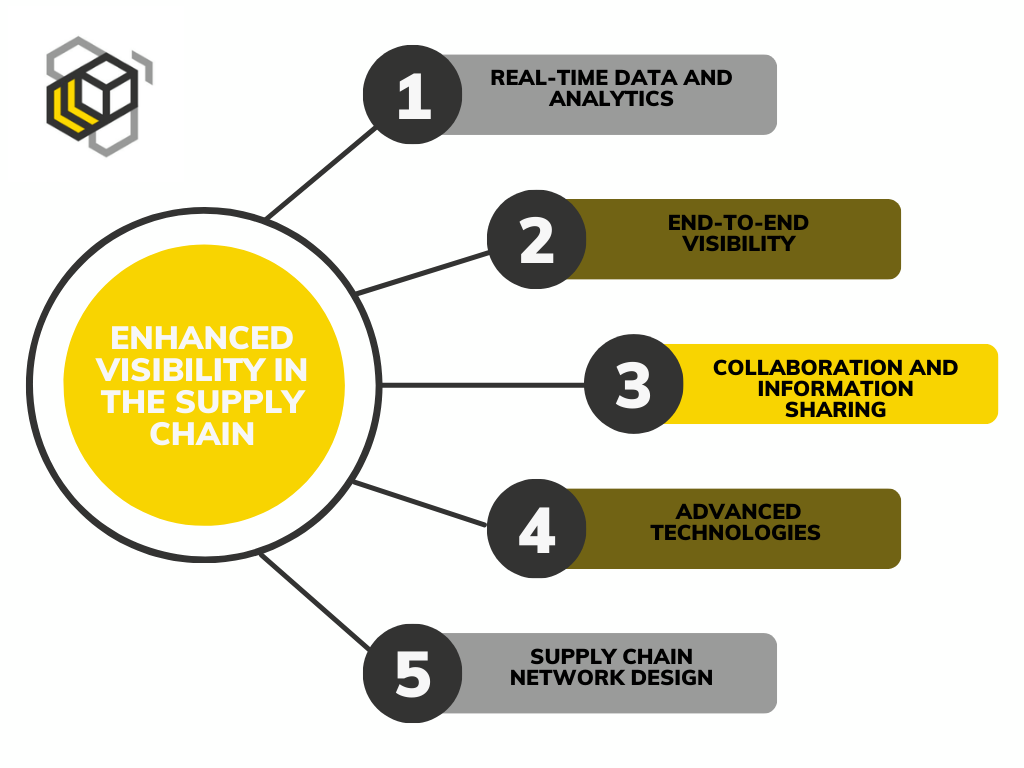

5 Factors for Enhanced Visibility in the Supply Chain

Greater insight across the supply chain is essential for resilient operations, a lack of risk and happy customers. Here are 5 pivotal elements for gaining comprehensive insight:

Companies should adopt these 5 crucial perspectives that are essential for executing end-to-end supply chain service much more effectively making better decisions, lower risks and keep customer satisfaction high.

Advantages of a Software-Driven Cold Chain

Using software, companies can raise product quality and customer satisfaction whilst minimizing waste. An efficient cold chain supported by scientific advances indicates a long-term value proposition for industries depending on goods whose efficacy is lost or destroyed if not kept within the prescribed temperature limits. This practice enhances execution and access to domain-specific knowledge by outsourcing software development to a trusted specialist team. Outsourcing software development to a reliable specialized team can turbocharge execution and provide access to sector-specific know-how.

Data-Driven Decision Making in Cold Storage

Modern business runs on data, and the cold storage industry is not immune. It helps companies to better understand their core operations, use resources efficiently and overall performance improvement.

The Importance of Data Collection and Analysis

Software solutions allows the vast amounts of data being produced in cold storage facilities to be compiled, stored and assessed. Data can be collected to provide tangible insights such as temperature and moisture readings, or less straightforward information like inventory levels and energy usage.

Use Data To Improve Operations

There are many advantages to an insight engine powered by data. For example, analyzing energy consumption patters can identify optimization opportunities to lower operational expenses. They are able to improve their stocking strategies, and reduce the waste by tracking the levels of inventory and turnover of products. Using equipment performance data, predictive maintenance models can identify and avoid breakdowns.

At the end of the day, cold storage facilities make quality decisions empowered with data that enable them to work more effectively and keep customers happy.

Conclusion

Cold storage companies then need specific tech solutions to simplify complex logistics of this era. More expensive at the starting points, custom-built software generates an array of long-term advantages — by cutting down costs and maximizing efficiency through personalized programs. They also ensure high-quality goods in an ongoing fashion, with the reliability of precision-engineered applications that keep systems to exacting standards. We encourage that this reignite creative coding rather than push it down, what will make us everybody else in the cold Supple industry. Contact our staff to gain insight on how we can modify operations with innovation in order to fit your benefit providing systems.